The carbon footprint of a stamper

Peter Frings

28 November 2023 (updated 30 May 2024)

How can the vinyl record industry reduce its contribution to the climate crisis? Is buying a physical record more damaging to the environment than streaming music?

Questions like these get discussed a lot at Making Vinyl conferences and within music trade associations – but there isn’t much data or hard evidence to inform the debates.

Stamper Discs is working with other businesses across the whole vinyl record supply chain to try to tackle this information vacuum. We’ve set ourselves the objective of carbon footprinting the whole lifecycle of a vinyl record.

Because until we have the data on the carbon emissions that result from manufacturing and distributing vinyl records, we can’t talk authoritatively about the sustainability of our industry. And we can only start to reduce our emissions when we know the make up of our carbon footprint.

I’ll post more on this initiative soon. But in the meantime, as part of this industry-wide project, we’ve calculated our own carbon footprint at Stamper Discs – both as an organisation, and also the footprint for an individual stamper.

Our organisational carbon footprint

In our last financial year, (March 2022 to February 2023) our total organisational footprint was 206.12 tonnes CO2e.

This is a ‘cradle-to-gate’ footprint which includes all of our Scope 1, 2, and 3 emissions.

As the illustration at the top shows, nearly 86 % of our total footprint comes from the Nickel we use in our plating baths, and the lacquers that are supplied in to us.

(All lacquers are currently manufactured in Japan – and the carbon cost of air-freighting them to Europe is a significant element in our overall footprint.)

All our electricity was purchased from a 100% renewable supplier – which is the biggest single step under our direct control.

What is the footprint of a stamper itself?

We primarily produce 12” stampers – 7” and 10” stampers only make up 3% of our output. Although they use less nickel to produce than a 12” – which is the biggest single component of our footprint – paradoxically they do require a longer plating time. And in most instances, 7” and 10” are cut onto 14” lacquers, making them identical to a 12” in terms of nickel used. For these reasons we have attributed our organisational footprint as though every stamper was 12”.

The way we have done this is to separate out the carbon footprint associated with lacquers/DMMs and applied this just to the 1st step stamper/metalwork piece. The balance of our organisational carbon footprint is then applied equally across all metalwork pieces produced during the year. This gives the following footprints for different stamper products:

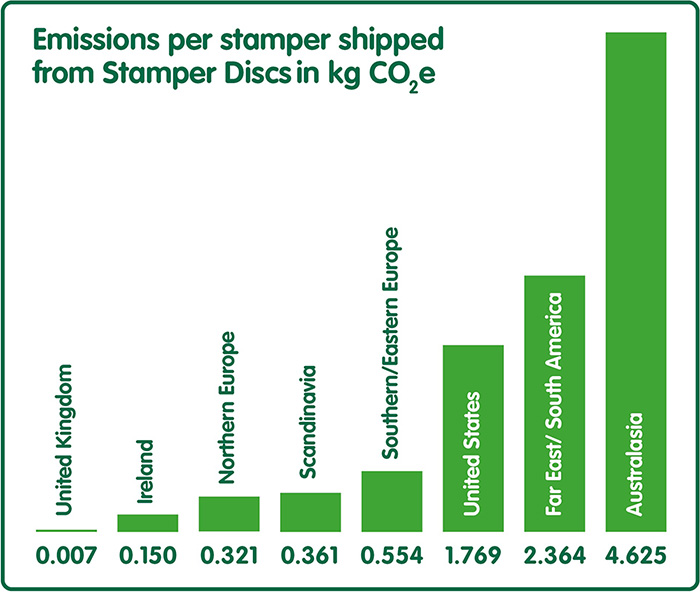

What about shipping the stampers to a pressing plant?

We use DHL or UPS to ship stampers to our customers. Within the UK, they are transported by road, and to overseas destinations, by air and road. We typically ship boxes of 8 to 10 stampers a time, and the shipping footprints below are based on that. The footprints have been calculated using the DHL Calculator. To keep the chart below manageable, we’ve grouped destinations together geographically. (For example, we ship to plants in Denmark, Sweden and Norway – the Scandinavia figure below is an average of the footprints across these three plants.) But we can supply a shipping footprint to an individual plant on request.

Questions you may have…

Is your carbon footprint independently audited? Yes. It has been validated by Climate Partner.

What methodology did you use. GHG Protocol Guidelines. Data was collected from our accounts system across every purchase made during the financial year, plus production data on number of lacquers received, stampers shipped etc. 87% of our footprint is based on primary data and official emissions factors. The major area where we have had to rely on secondary data is for lacquer manufacture.

Can I see the detailed footprint? Yes, if you are a customer of ours. But a more detailed summary, and a copy of the Validation Statement from Climate Partner, can be seen in the First Carbon Footprinting Report published by the VRMA.