Our guide to shipping lacquers safely

Martin Frings

22 February 2024

We receive hundreds of lacquers every week from all over the world. 99% of the time these arrive with us in fantastic condition and can go straight into production. But just occasionally lacquers do get damaged in transit. Here’s our advice on how to make sure your lacquers have the best possible protection from rough handling by couriers.

This article is meant to serve as a guide for best practices with the widely used pizza style box adopted by most cutting studios, not necessarily as the ultimate way of shipping a lacquer. For some cutting studios who are thinking outside of the (lacquer) box see the end of the article.

The box

The industry norm has been to use the pizza-style boxes provided by the lacquer supplier. A key design feature of these boxes is the reinforced corner columns (fig. 1). We have seen some lacquers shipped in pizza style boxes without such reinforced corners… We strongly advise against these as the damage rate for these boxes is high.

Fig. 1

If possible, always use a brand new box, that hasn’t been softened by repeated shipping. A new box is a fraction of the cost of a full box of freshly cut lacquers and cardboard is universally recycled.

But some cutting studios do prefer to re-use boxes multiple times, and largely do so without any issues. If you’d like to do this, we are happy to supply you with used boxes.

Spacing and reinforcement

Ideally, both the top and bottom of the box should be reinforced to create a cocoon around the lacquers, with a scrap lacquer placed last into the box to prevent a heavy knock from above damaging the top lacquer.

But in most instances it is sufficient to just reinforce the bottom of the box with either an old scrap record or a reject/processed lacquer. A robust base is essential as it’s not uncommon for the corner of a table or something similar to pierce the bottom of the box during shipping. The reinforcing scrap lacquer/record should be bolted to the bottom of the box with a washer and then secured with a nut and washer from inside the box.

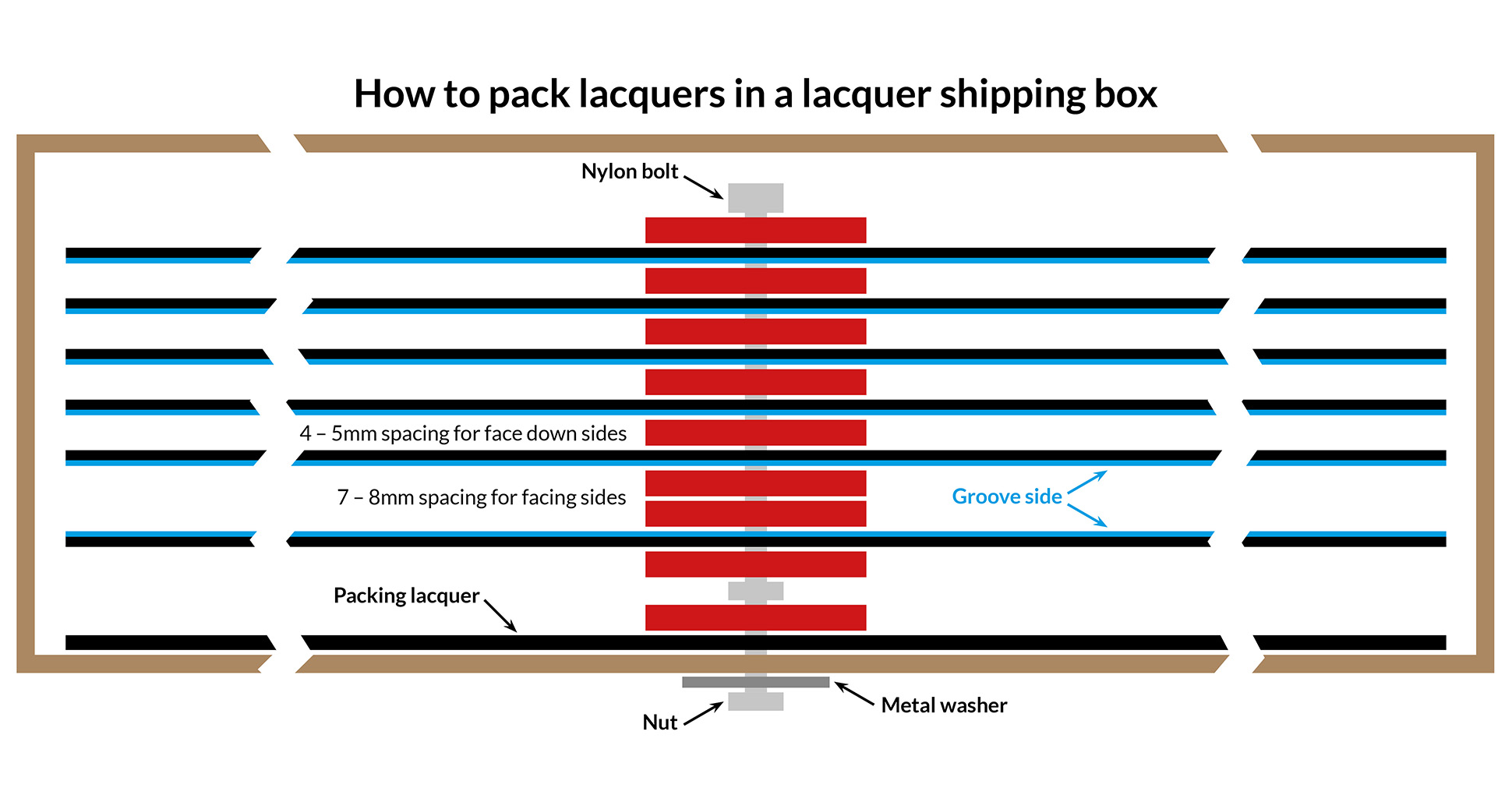

You should never have more than 6-8 lacquers per box. The bottom lacquer in the box should always be face up and raised up from the bottom of the box by at least 7-8mm by a couple of lacquer spacing washers.

Fig.2

All the following lacquers should be placed face down in the box after this. There is a tendency for the outer edges of lacquers to flex when knocked during shipping and lacquers can get ‘groove clash’ on the two facing discs at the bottom of the box (fig. 2) . An incredibly hard knock by a clumsy courier is sometimes unavoidable. But having at least 7– 8mm of space between these two facing sides should be enough to withstand most normal transport.

After the first pair are placed into the box all the remaining 4-6 lacquers can go in face down. It is rare for groove clash to ever occur when the the cut side is facing a new blank rear of a lacquer.

Because of this, 4-5 mm is all that is needed for spacing. But if the rear side of the previous lacquer in the box has been used for some test cuts, then it is advisable to treat it as a cut side – it will act as such if the box is dropped. We also recommend leaving a healthy amount of room at the top of the bolt and let this decide whether you include 6 or 8 lacquers. As a general rule the less lacquers the better. Obviously it is not always viable to only send a pair of lacquers per box, but always err towards less than more.

See below a diagram of well-stacked lacquers:

Nuts, bolts and washers

Nuts, bolts and washers

An M6 metal bolt, with a metal nylon-lined, non-loosening nut, is the preferred option when shipping lacquers. The length of your bolt will depend on the depth of your box and thickness of reinforcing material. Plastic bolts should be avoided as these often break.

Even a slight loosening of the clamping nut in shipping can create enough movement between the lacquers to create groove clash.

If you are not using a nylon-lined nut, you might be tempted to over-tighten a standard nut to make sure the lacquers don’t come loose in transit. But this tends to deform the soft aluminium base of the lacquer, which risks a poor contact on the plating jig and can result in plating issues.

An alternative approach used by some engineers if they don’t have nylon-lined nuts is simply to wrap a small amount of tape around the exposed top of the bolt to stop it travelling up and loosening.

Fig. 3

Fig. 4

Fibre washers with an internal diameter of 8 mm and an outer diameter of 30 mm are the standard for shipping lacquers and are sufficient, although some cutting houses do use washers as large as 60 mm outer diameter. Whilst these may take a bit of shopping around to find, we recommend using these as the larger the washer the more support it offers the lacquers. We don’t advise going above 60 mm though, as you need a small radius around the washer where you can pick it up without risk of cosmetically damaging the run-out area – which begins at 85mm for 7” records (fig. 3 and 4).

Finally whilst the bolt and nut should only be metal, the washers/spacers should be fibre or plastic so as they can absorb a bit of shock or over-tightening and do not leave harsh dents in the lacquer and aluminium.

Other considerations

Don’t ship more than 3 boxes of 6-8 lacquers as a single parcel. The cumulative weight soon adds up and makes the entire package much more prone to damage as the weight compromises the rigidity of the cardboard.

Fig. 5

Also, if re-using old lacquer boxes, check that no washers have worked their way under the flaps on the bottom of the box, or under the corner reinforcements. We have seen many lacquers ruined by these working their way loose in shipping and flying around the box leaving nasty scratches (fig. 5).

Lacquers are sensitive to variations in temperature, but the effect of temperature and shipping on lacquers has been over-emphasised by plants with their own cutting and plating facilities. Although issues are extremely rare, we would still recommend sending lacquers on a next-day delivery service, especially in the height of summer.

Labelling and documentation

In order for us to ensure all lacquers are booked in efficiently, please attach a label or a document to the outside of the lacquer box which clearly states the catalogue number of each lacquer and the number of sides. Recuts should be identified with a ‘2’ or ‘3’ etc., added to the matrix number. Please also state who the customer is for the job on the outside of the box. If a label/ artist/ broker has placed the order with the cutting studio, please ask them to confirm which pressing plant the stampers should be sent to once the lacquers have been processed. Having all of this information on the outside of the box means there is no unnecessary handling of lacquers before they go into production.

Thinking Outside the lacquer box

The pizza style box may be destined to last forever but here are some great alternatives. Let us know if we missed yours and we can add it below!

Fig. 6

Agnew Analog Reference Instruments

The Rolls Royce of lacquer shipping boxes, made from beech and beech plywood these shipping boxes are designed to withstand ‘several years’ of shipping abuse. It is also claimed by Agnew that the wood provides greater thermal insulation than its cardboard counterpart.

The only downside is the very hefty shipping charge to return it to you each time – especially if used internationally. But if you’re a cutting studio that wants to make a statement about quality at any expense… (fig. 6).

Fig. 7

NiPro Optics

Another great and reusable approach to lacquer shipping. The benefit this has over every single other design is the plastic casing ensures no cardboard or wood fibres can get anywhere near the lacquer. We all know what dust in the grooves can sound like and this design ensures each lacquer is sealed from any contamination (fig. 7).

Fig. 8

Capitol Records ‘Master Pak’

A styrofoam design from Capitol gives the ultimate temperature insulation and the thick robust walls that fit into a cardboard sleeve mean that it’s virtually indestructible. The novel approach to the centre spindle of just having a locating rod and interchangeable spacers means that the lacquers are perfectly suspended and have no risk of coming in contact with the walls (fig. 8).

Fig. 9

Telegraph Mastering

Finally we have a simple but ingenious design from Telegraph Mastering, the robust cardboard sleeve houses a cardboard platter that can slide clean out. The real genius of this design is the firm foam corner supports, these are placed so as to offer some resistance to the very outside of the lacquers diameter which means they give some support to the outer edge and rule out any risk of groove clash (fig. 9).