The physical attributes of a stamper – thickness uniformity

Martin Frings

30 January 2025

In a previous post, I discussed the weight and the thickness of a stamper. One conclusion was that the weight of a stamper only tells you the amount of nickel present… but doesn’t necessarily mean that the nickel is evenly deposited across the whole stamper.

In this second post on the physical attributes of stampers I’ll be looking at the ‘thickness uniformity’ of a stamper.

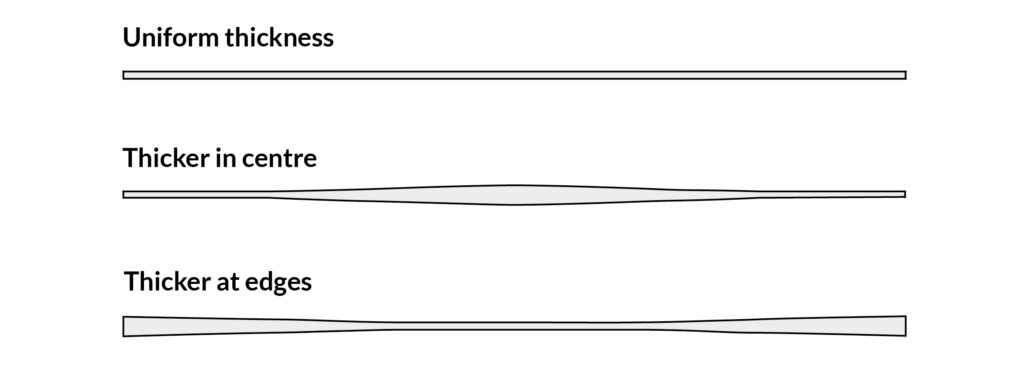

The diagram below shows some scenarios of uneven nickel deposition in a stamper and how it might present itself.

Why should you worry about the thickness uniformity of your stampers?

Why should you worry about the thickness uniformity of your stampers?

There are a whole raft of issues associated with an uneven stamper. Many of these are touched on in the post on stamper thickness and how it affects stamper life as well as press cycle times.

A stamper that is dramatically thinner at the centre (<200microns) will break prematurely. And vice versa for the outer edge.

In some old EMI baths there was actually an effort made in the design of the plating cell to create a stamper that is purposefully thicker in the centre (where the centre bushing sits) to lengthen the lifespan of stampers on press by strengthening this most common failure point.

If a stamper breaks very early during the press cycle and the centre bushing is sunken then this is a fairly easy diagnosis to make, but some of the other issues created by a lack of uniformity can be much harder to diagnose.

A stamper that is significantly thicker towards the outer diameter can cause non-fill on the run-in and first track as a result of the effect greater thickness has on heat transfer from the mold.

A stamper that has an appropriate thickness at the outer and inner diameters yet has a thin band in the mid-diameter area can also create a small cavity between the stamper and the mold which leads to an increase in pitting as the pressing process goes along and the movement of the stamper allows residue to build up.

Issues such as non-fill and pitting can of course have a multitude of other causes as well – so diagnosing them as a result of uneven stamper thickness can be tricky.

What is an acceptable range of thickness uniformity?

In most precision plating applications in other industries an acceptable thickness variation is regarded as being around 20 microns.

Tolerances are tighter in disc media: 10 microns for an audio CD stamper, 5 microns for DVD, and 3 microns for BluRay.

Stamper Discs aims to stay within the CD stamper thickness tolerance – although it is unlikely there will be any problems on the press with stampers up to 20microns ‘Total Thickness Variation’ (TTV). 20 microns TTV is a very achievable range for any stamper manufacturer.

What causes stampers to have an uneven thickness?

The largest contributing factor to variations in stamper thickness uniformity is the bath design – specifically the relationship between the anode and the cathode in the plating cell.

After that the control rings around the outer diameter of the disc, (that are used to create and seal the edge during plating), are the second largest contributing factor.

Flow rate and jig rotation speed can also have an impact.

But there is almost nothing in the course of daily production that has a significant effect on thickness uniformity. There are baths on the market and in production that do not lend themselves to uniform deposits – but if you are happy with the stampers from your stamper supplier then it is not a parameter that will vary greatly from stamper to stamper, and you can rule out variations in stamper thickness as the cause of any issues on press.

What is the best way of measuring the thickness uniformity of a stamper?

One historical method is the technique adopted by the CD industry using a machine manufactured by ADE. This used non contact capacitive sensors to take a thickness reading of optical disc stampers. A vinyl stamper supplier has ‘adapted’ this for vinyl records, but it is not able to measure the full radius of the stamper. Because it measures the thickness uniformity on only half of the radius of a vinyl stamper, the data provided isn’t too useful, and the machine is also no longer in production.

One of the most precise measurement devices that exists today is the Thickness Tester manufactured by Micro Epsilon. By using two opposing confocal lenses they are able to have a contact free reading within a tolerance of 0.2microns that will give you a profile of the whole radius of the disc.

The cost of this and similar systems are a barrier to uptake in the vinyl record industry where measurement to tolerances of 0.2microns is not essential.

No-contact and non-destructive measurement tools like the ones from ADE and Micro Epsilon are also – to a large extent – inappropriate for vinyl records. Whilst the pit depth on an optical disc may be as little as 0.1 microns, the groove depth on a vinyl record may be as deep as 40 microns.

Hence the readings from these highly precise ‘no-contact’ measurement methods are only meaningful if you use a blank stamper.

And if the only accurate way to get a reliable measurement of stamper thickness is to grow a blank stamper especially for the purpose of testing… then does it matter if the testing method is ‘non-contact’?

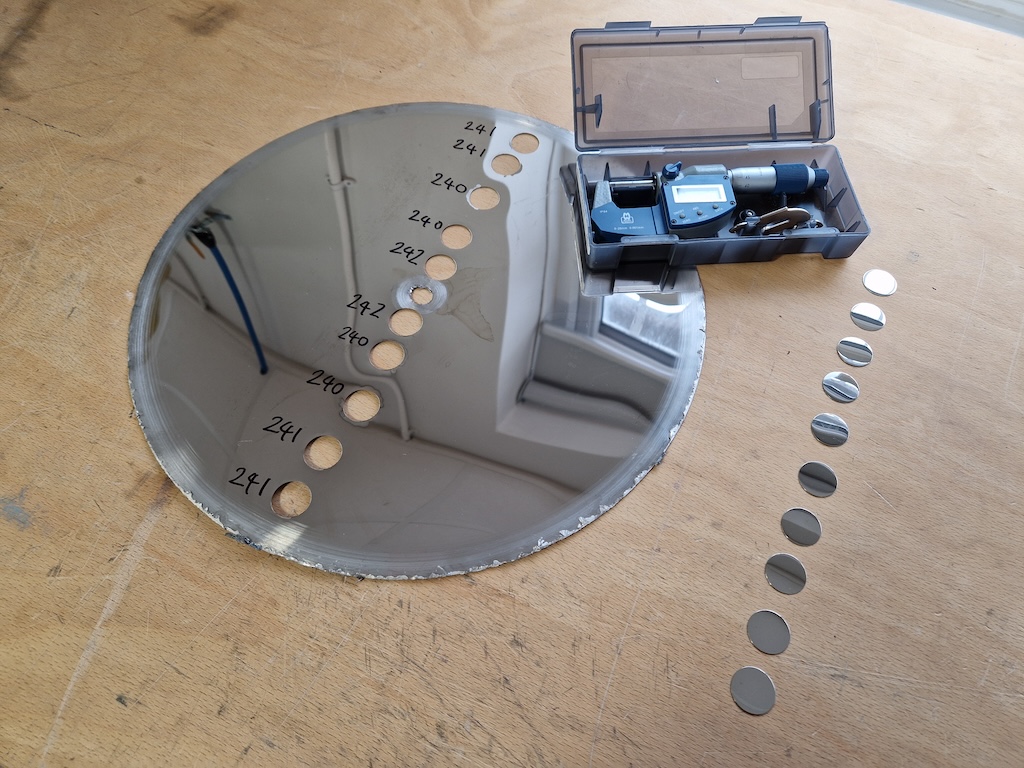

For these reasons, at Stamper Discs we conduct periodic 10 point readings across the surface of a blank stamper with an accurate micrometer. It is possible to either cut a strip with a pair of tin snips or number and punch out 10 small circles using a centre punch.

What about a press operator who wants to check a stamper?

What about a press operator who wants to check a stamper?

If you are a pressing plant that would like to compare stampers from different suppliers, or to check a stamper before or after it goes onto the press, then you need a non-destructive method of checking the thickness uniformity of a stamper.

If you are a pressing plant that would like to compare stampers from different suppliers, or to check a stamper before or after it goes onto the press, then you need a non-destructive method of checking the thickness uniformity of a stamper.

A deep throated sheet metal micrometer is a good tool for this purpose. These micrometers are designed to test sheet metal thickness away from the edge of the sheet – which means there are many models that can accommodate the full radius of a stamper.

They are readily available on the second hand market for <£100 and with some additional ball attachments it is possible to take a very accurate reading of the land at the end of the grooves whilst leaving almost zero cosmetic defects.

They are readily available on the second hand market for <£100 and with some additional ball attachments it is possible to take a very accurate reading of the land at the end of the grooves whilst leaving almost zero cosmetic defects.

It is important that readings are only taken on the shoulder of the record, or the land at the end, to avoid any risk of damaging the groove structures. But even these two quick readings should tell you with a high level of confidence if your stamper is within the right ballpark and allow you to rule out stamper thickness as a potential cause of problems on press.